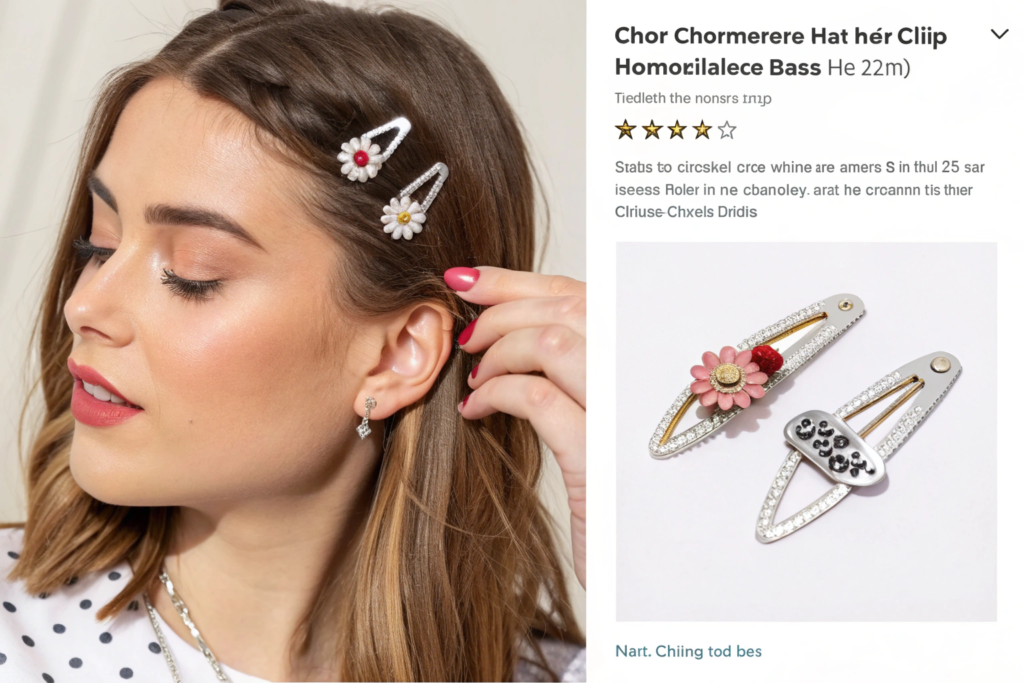

As a manufacturer in the hair accessories industry, I frequently encounter clients like Ron, who are looking for innovative and customizable products to stand out in the market. One of the most popular and growing trends is the interchangeable hair clip charm system. These clever designs allow end consumers to attach and swap different decorative charms on a single, sturdy clip base, offering endless customization.

The journey to finding a reliable manufacturer for an interchangeable charm system is not about finding one magic supplier. Instead, it requires understanding the distinct components involved—the functional clip base and the decorative charms—and then identifying the right production partners for each. It’s a supply chain puzzle where specialization is key.

Let’s break down this sourcing process. We'll first explore why specialized sourcing is necessary, then delve into the specific types of manufacturers you need for each component, and finally discuss how to bring it all together into a cohesive, sellable product. This knowledge will help you streamline your development and find the best partners efficiently.

What Makes Sourcing Interchangeable Charm Systems Different?

Sourcing a standard hair clip is straightforward. You find a factory that makes the style you want, and you’re done. An interchangeable system, however, is a product ecosystem. It involves multiple parts that must work together seamlessly, which changes the entire sourcing strategy.

Sourcing interchangeable charm systems is fundamentally different because you are not looking for one single manufacturer; you are building a supply chain for a modular product. The challenge lies in finding specialized expertise for two distinct components: 1) the engineering and production of a reliable, reusable clip mechanism with a standardized attachment point, and 2) the creative design and production of diverse, appealing decorative charms that securely fit that attachment. Very few factories excel at both precision engineering and high-volume, varied decorative manufacturing.

Consider the design requirements. The clip base must be engineered for repeated use—opening, closing, and having charms snapped on and off hundreds of times without failure. This demands high-quality materials and precise molding or metalwork. The charms, conversely, are about aesthetic variety, lightweight design, and cost-effective production in smaller batches across different materials (metal, resin, acrylic, felt). Trying to force a charm factory to engineer a flawless clip mechanism, or a precision metal factory to produce thousands of whimsical felt flowers, leads to compromised quality and higher costs. Recognizing this division of labor is the first step to successful sourcing. This is precisely why integrated suppliers like Shanghai Fumao Clothing, which manages complex production streams from clip manufacturing to final assembly and quality control, become invaluable partners for such projects.

Why is the Clip Base the Most Critical Component to Source?

The clip base is the foundation of the entire system. Its failure means the entire product fails, regardless of how beautiful the charms are. You need a manufacturer with proven experience in producing durable, functional hair clips—think companies that supply hair clips, claw clips, and barrettes to major brands. Their expertise in selecting the right spring tension, ensuring smooth opening action, and using materials that won't snap or deform is non-negotiable. When discussing your project, you must specify that the clip design must incorporate a standardized, secure attachment point (like a socket, post, or magnet array) for the charms. This is where you leverage a manufacturer's OEM/ODM capabilities for custom design.

How Does the Charm Sourcing Strategy Impact Your Business Model?

Your approach to sourcing charms defines your brand's flexibility and scalability. Working with specialized accessory manufacturers (for hairpin charms, small fashion accessories, etc.) allows for incredible variety. You can source charms from multiple suppliers to build a vast, trend-responsive collection. However, this requires you to manage quality and fit consistency across different factories. The alternative is to develop custom charms with a single, capable factory that can handle diverse materials. This ensures uniformity but may limit initial design options. Your choice here impacts your minimum order quantities (MOQ), lead times, and ability to quickly launch new charm lines in response to fashion trends.

Where to Source the Precision Clip Base and Mechanism?

The quest for the perfect clip base leads you to established manufacturers of functional hair accessories. These are typically not the glittery, decorative-focused shops, but the behind-the-scenes producers of reliable, everyday items.

You will find proficient manufacturers of high-quality clip bases in major Chinese manufacturing hubs. Guangzhou and the broader Guangdong province are renowned for hardware, plastics, and metal fabrication, making them ideal for finding factories that produce the core mechanisms. These manufacturers often supply to global brands and have the engineering prowess to develop a custom base with your specified attachment system. Look for suppliers that advertise OEM services, custom design, and highlight their quality control processes. Their product lines will often include basic bobby pins, claw clips, and barrettes, indicating a focus on function over decoration.

When evaluating a potential clip base supplier, move beyond their catalog. Engage them in a technical discussion. Present a prototype or detailed sketch of your desired attachment mechanism (e.g., a central post with a locking groove, a magnetic plate, or a snap socket). Ask pointed questions: Can you engineer this? What material (e.g., reinforced nylon, ABS plastic, zinc alloy) do you recommend for durability and cost? What is the estimated cycle life (open/close actions) of the prototype? Their ability to answer these questions confidently is more important than a slick website. Platforms like Alibaba can be a starting point, but for critical components, nothing replaces factory visits or detailed sample evaluations to assess their production capacity and quality assurance firsthand.

What Should You Look for in a Clip Base Manufacturer's Portfolio?

Scrutinize a manufacturer's existing products for clues about their capability. Do they produce items with moving parts, springs, and precise tolerances? A factory that makes simple, non-mechanical headbands or scrunchies may not have the right equipment or expertise. Instead, prioritize those whose main offerings are hair clips, claw clips, and functional hair pins. Check if they have certifications like ISO9001, which speaks to a systematic approach to quality management. Furthermore, review their trade show participation (e.g., Canton Fair); attendance often signals a more established and export-oriented business.

How Can You Prototype and Test the Interchangeable Mechanism?

Before committing to mass production, insist on multiple rounds of sampling. The first sample should test the basic clip function and ergonomics. The second, more critical sample should include the attachment mechanism and a few test charms. Conduct rigorous in-house testing: attach and detach a charm 500 times. Does it hold firmly? Does the locking mechanism wear out or become loose? Test the clip with different hair weights and textures. Share this feedback with the manufacturer for refinements. This iterative process, though time-consuming, is the only way to ensure a successful product launch and avoid costly returns. A supplier experienced in custom design will expect and facilitate this process.

Where to Source Diverse and Stylish Decorative Charms?

Once your clip base is solidified, the fun begins: sourcing the charms that give your system its personality and market appeal. This is where you tap into a different segment of the supply chain—creativity-driven accessory specialists.

For the decorative charms, look to centers of fashion accessory manufacturing like Yiwu in Zhejiang province, famous for its vast wholesale markets for small commodities and fashion accessories. Here, you'll find countless suppliers specializing in specific charm types: metal charms, acrylic pendants, resin decorations, felt shapes, and pearl clusters. These suppliers excel at high-volume, cost-effective production of decorative items and are highly responsive to trends. Their strength is in aesthetics and variety, not in engineering mechanical parts. You can work with them by providing the exact specifications of the connector on the back of the charm (e.g., the size of a hole, the type of glue pad, or a specific snap-fitting design) that matches your clip base.

The strategy here is often multi-sourcing. You might get enamel charms from one factory in Dongguan, laser-cut acrylic charms from another, and miniature fabric bows from a third. This allows you to build a rich and diverse collection. The key is to provide all charm suppliers with a physical "master connector" or an extremely precise technical drawing. This ensures that every charm, regardless of its face design, will fit your clip base perfectly. When dealing with these factories, be very clear about material specifications, color matching (providing Pantone codes), and finish quality (e.g., no sharp edges, consistent plating). Their minimum order quantities (MOQ) for individual charm designs can be relatively low, allowing for a broad SKU range without excessive upfront inventory cost.

What Are the Benefits of Sourcing Charms from Specialized Factories?

Specialized charm factories offer three major advantages: trend speed, material expertise, and cost efficiency. They are often smaller and nimbler, quickly adapting to new fashion trends seen on platforms like TikTok and Instagram. A factory that only works with felt will have deep knowledge of fabric grading, cutting techniques, and color fastness. Another that specializes in zinc alloy charms will be an expert in detailed molds and plating finishes. By dividing your charm orders among these experts, you get the best possible version of each charm type, often at a better price than a general-purpose factory could offer.

How Do You Ensure Quality and Consistency Across Multiple Charm Suppliers?

Maintaining consistency is the central challenge of multi-sourcing charms. The solution is a robust quality control (QC) protocol centered on the connector. Create a "go/no-go" gauge—a simple tool that tests if the charm's connector fits the clip base correctly. Ship this gauge to each charm factory and require pre-shipment samples. Secondly, establish clear acceptance quality limits (AQL) for cosmetic defects like painting errors, scratches, or inconsistent glitter application. As the systems integrator, you or your partner must take ownership of final inspection before the charms are paired with clips and packaged, catching any mismatches or sub-par items from the various sources. This is a core part of the end-to-end service that Shanghai Fumao Clothing provides, ensuring every component meets the same high standard.

How to Assemble and Package the Complete System for Market?

With the clip bases and boxes of charms in hand, the final, crucial step is to bring them together into a single, market-ready product. This stage transforms components into a compelling consumer proposition.

Final assembly and packaging are where your product vision comes to life. This process typically involves receiving bulk shipments of clips and charms, then conducting a kitting operation: manually or semi-automatically pairing one clip base with a selection of charms (e.g., 1 clip + 3 charms) and placing them into retail packaging. This requires a clean, organized assembly line and careful quality control to ensure every set is complete and damage-free. The packaging itself must clearly communicate the product's unique selling proposition. It should showcase the charms, explain the interchangeable function simply, and have a design that stands out on shelf or in an online store thumbnail.

Your packaging strategy is a key marketing tool. Consider clamshell packs that allow the product to be seen and touched, or elegant boxes that position it as a giftable item. The packaging must also be functional: it needs to securely hold the clip and its accompanying charms, often using custom plastic inserts or blister cards. This is another area where an integrated supplier shows its value. A partner with control over production, inspection, and packaging can streamline this entire process, ensuring that the components they produce or source are assembled correctly, efficiently, and to a uniform standard before being shipped directly to you or your fulfillment centers.

What Are the Key Considerations for System Assembly?

Efficiency and accuracy are paramount in assembly. You must decide on the kit configuration (How many charms per box? Which charm designs are bundled together?). The assembly facility needs a clear process to prevent errors, like packing the wrong charm or missing a component. Implementing a final checkpoint where each completed box is weighed or scanned can catch incomplete sets. Furthermore, consider the unboxing experience for the end customer—the packaging should make the product easy to understand and use immediately, reinforcing the value of your interchangeable system.

Why is Professional Packaging Design Non-Negotiable?

For an interchangeable system, the packaging is your primary salesperson. It must instantly answer the customer's question: "What is this and why is it special?" Use visuals and icons to demonstrate the charm-swapping feature. Include brief, multilingual instructions if you are targeting global markets like the US and EU. High-quality packaging also protects the product during shipping and enhances its perceived value, allowing for a stronger retail price point. Investing in professional packaging design and durable materials is a direct investment in your brand's reputation and customer satisfaction. The packaging factory in our network at Shanghai Fumao Clothing specializes in creating such market-ready solutions that align perfectly with your brand identity.

Conclusion

Finding a manufacturer for an interchangeable hair clip charm system is a sophisticated sourcing project that mirrors the modularity of the product itself. Success lies not in finding a single factory, but in strategically identifying and managing two specialized supply chains: one for the precision-engineered clip base and another for the diverse, fashionable decorative charms. The final step of cohesive assembly and market-ready packaging is what transforms these components into a desirable, retail-ready product.

For wholesalers, brands, and retailers, navigating this process requires time and supply chain expertise. However, the payoff is a highly customizable, trend-responsive product with strong customer appeal and repeat purchase potential.

If you are looking to develop a successful interchangeable hair accessory line but want to avoid the complexity of managing multiple suppliers and assembly, we can be your single-point solution. Shanghai Fumao Clothing specializes in managing exactly this kind of integrated production, from custom clip engineering and charm sourcing to final QC and packaging. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss bringing your interchangeable charm system concept to market efficiently and at scale.