Designing hairpins with fine shapes, layered elements, or interlocking parts has always been a challenge in mass production. Traditional mold-making can be costly and time-consuming, especially when buyers want fast development or frequent design revisions.

Factories that offer in-house 3D prototyping help buyers accelerate sampling, reduce errors, and bring innovative hairpin concepts to life with unmatched speed and flexibility.

In this article, I’ll share why working with a factory like HairAcc, equipped with 3D prototyping capabilities, is a smart move for brands dealing with complex hair accessory designs.

What Is 3D Prototyping in Hairpin Manufacturing?

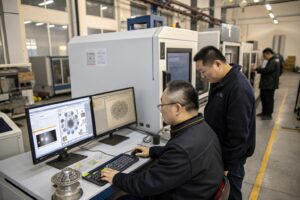

3D prototyping refers to using digital modeling and rapid printing to create early-stage physical samples of hair accessories before full-scale production.

How Does 3D Prototyping Work?

Our designers create a 3D model using CAD software like SolidWorks or Rhino. The design is then printed using resin or ABS plastic with micron-level precision. Within hours, clients can see and test a real physical sample that mirrors the final shape, curves, and fitting.

This process allows quick iterations, enabling brands to test multiple sizes or design variants in days—not weeks. Formlabs explains how this tech reduces sampling bottlenecks across industries.

Why Is It Valuable for Hair Accessories?

Hairpins often include intricate decorative elements—floral petals, metallic filigree, or interlocking clasps. 3D printing helps test these micro features for durability and styling impact before committing to expensive molds. It's especially helpful for boutique and seasonal collections where time and detail matter.

What Hairpin Design Challenges Does 3D Printing Solve?

Complex hairpin designs often fail not because of bad ideas, but because of missed technical issues in early development.

What Are the Common Failure Points?

Hairpins can break or feel uncomfortable due to:

- Weak junctions between decorative parts and metal base

- Misaligned clasps or hinge tension

- Protruding edges causing scalp irritation

- Overweight embellishments that don’t balance in hair

With 3D mockups, we can test these issues through tactile inspection and comb-through simulations before committing to tooling.

Can 3D Models Be Used for Marketing Too?

Yes. Many clients request rendered models for pre-launch promotions or to secure retailer buy-ins. We use photorealistic 3D visuals to present new hairpin designs to buyers—before physical production even starts. This is key for crowdfunding, early access sales, and fashion drops in the digital age.

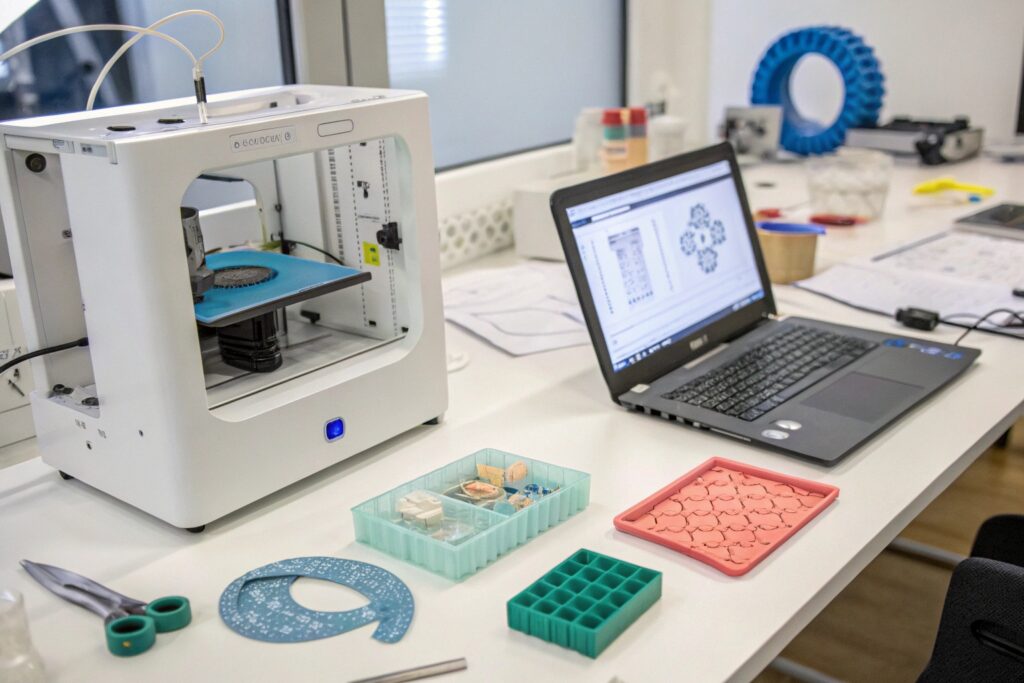

How Does 3D Prototyping Reduce Time and Cost?

In traditional manufacturing, a single mold for a decorative hairpin can take up to 3 weeks and cost over $1,000 USD.

What’s the Time Savings?

| Method | Sampling Time | Sample Cost (USD) | Modifications |

|---|---|---|---|

| Mold-Based | 14–21 days | $800–$1,500 | Expensive, slow |

| 3D Prototyping | 1–3 days | $50–$200 | Fast and easy |

With in-house printers, we can test-fit 3–5 variants in under a week. This enables clients to finalize collections faster, reduce R&D lag, and meet trend windows efficiently.

What’s the Cost Impact for Small Orders?

For brands placing 1,000–3,000 units, mold amortization can make unit costs higher. By contrast, 3D printing enables market testing before investing in molds. Even after mold development, prototyping keeps revisions economical. Learn more about the benefits at 3Dnatives.

How Does HairAcc Handle 3D Prototyping in Hairpin Development?

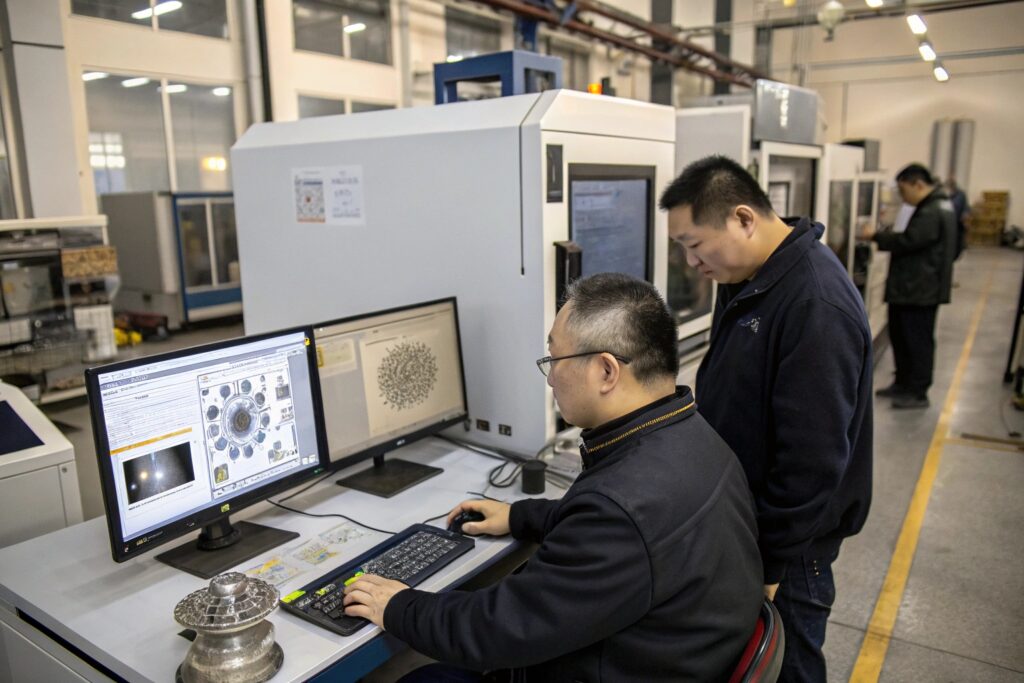

At HairAcc, 3D prototyping is part of our standard development workflow for complex hair accessories like layered pins, novelty shapes, and interlocking clips.

What Services Do We Offer?

We support:

- CAD modeling based on hand sketches or reference images

- 3D printed resin prototypes within 48 hours

- Fit and tension testing for clips and clasps

- Feedback loops via video or physical delivery

- Mould-ready file preparation once design is approved

This ensures smoother communication, fewer production errors, and faster finalization.

Can Clients Request Revisions Remotely?

Yes. We work with overseas buyers who view 360-degree video previews or receive prototypes via DHL. Revisions can be made overnight. Our factory integrates platforms like GrabCAD for shared model access and updates in real-time.

Conclusion

Choosing a hair accessory factory with 3D prototyping isn’t just a smart technical move—it’s a creative advantage. From intricate bridal pins to quirky seasonal designs, 3D sampling helps you turn ideas into reality faster, cheaper, and more accurately.

At HairAcc, we don’t just manufacture—we co-create. Our in-house 3D services empower global buyers to innovate without fear of delay or waste. If you’re working on a line of complex or custom hairpins, we invite you to try our 3D development approach.

Let us help you bring your designs to life—flawlessly and fast.