Hair vines integrated with fiber optic lighting represent a specialized intersection of fashion technology and wearable innovation, requiring sourcing approaches that combine traditional accessory manufacturing with specialized lighting component expertise. These products present unique technical challenges related to power supply miniaturization, flexible lighting integration, and safety compliance for wearable electronics.

The most effective sourcing paths for hair vines with fiber optic lighting include specialized wearable technology manufacturers, collaborations between accessory producers and fiber optic specialists, custom development with LED technology companies, and direct partnerships with designers working in fashion-tech innovation. Each approach offers different advantages in technical capability, minimum order quantities, customization potential, and production scalability. Understanding these sourcing strategies helps businesses identify appropriate partners based on their technical requirements, production volumes, and market positioning.

The market for illuminated hair accessories remains niche but growing, with particular interest from the festival fashion, performance costume, and special events markets. Let's explore the most productive sourcing approaches for these innovative fashion-tech products.

Which Wearable Technology Specialists Produce Fiber Optic Hair Accessories?

Wearable technology specialists with expertise in fashion integration represent the most direct sourcing channel for ready-to-market fiber optic hair vines. These companies understand both the technical requirements of illuminated accessories and the aesthetic expectations of fashion consumers.

Companies like Luminae Accessories have developed proprietary fiber optic integration systems specifically for hair accessories. Their technology typically uses side-emitting optical fibers woven into decorative patterns with micro-LED light sources concealed in compact control modules. According to market analysis from Wearable Technology Magazine, companies specializing in fashion-tech illumination have seen 56% year-over-year growth, with hair accessories representing approximately 18% of their product lines. These specialists typically offer customization options including pattern variations, color programming, and control mechanism placement while maintaining compliance with safety standards for wearable electronics.

Performance costume technology companies like StageFX Illumination bring expertise from theatrical and entertainment applications to fashion accessories. Their hair vines often feature brighter illumination, multiple lighting modes, and robust construction designed for active wear. The International Association of Amusement Parks and Attractions reports increasing crossover between performance costume technology and fashion accessories, particularly for festival and event markets. While these products may have higher power requirements or slightly less delicate aesthetics than pure fashion-focused options, they offer proven durability and visibility in low-light environments, making them particularly suitable for night markets, concerts, and special events.

What Technical Specifications Are Critical for Fiber Optic Hair Vines?

Evaluating fiber optic hair vines requires attention to specific technical specifications beyond aesthetic considerations. Optical fiber diameter (typically 0.5-2mm) affects both flexibility and light intensity. LED source specifications including lumens output, color rendering index, and power consumption determine visibility and battery life. Control system features like programmable patterns, wireless connectivity, and waterproof ratings impact user experience. Battery specifications including capacity, rechargeability, and runtime determine practical usability. Safety certifications for wearable electronics provide assurance of proper insulation and heat management. These technical factors differentiate professionally engineered products from DIY solutions that may compromise on safety or performance.

How Can Businesses Assess Wearable Tech Manufacturer Expertise?

Assessing wearable tech manufacturer expertise requires evaluating both technical capabilities and fashion sensibilities. Request documentation of electrical safety testing for wearable applications. Examine product portfolios for evidence of successful fashion-tech integrations, not just technical components. Inquire about design collaboration processes to ensure aesthetic considerations are incorporated from initial development stages. Check for industry-specific certifications like CE/FCC for electronics and textile safety standards. Request user testing data regarding comfort, wearability, and durability in real-world conditions. Manufacturers with genuine expertise will provide comprehensive documentation addressing both technical and user experience considerations.

What Collaborative Approaches Between Accessory Makers and Lighting Specialists Are Effective?

Collaborative approaches that bring together traditional accessory manufacturers with specialized lighting companies can create superior products by leveraging complementary expertise. This model allows each partner to focus on their core competencies while creating integrated solutions.

Partnerships between hair accessory specialists and fiber optic component manufacturers have produced some of the most innovative illuminated hair vines on the market. In these collaborations, accessory designers create the aesthetic framework and wearability solutions while lighting experts handle illumination technology integration. Industry analysis from Fashion Tech Connect indicates that collaborative development models reduce time-to-market by approximately 40% compared to single-company development efforts. The most successful partnerships establish clear division of responsibilities from the outset, with regular integration checkpoints to ensure technical and aesthetic alignment throughout development.

Contract manufacturing networks that include both soft goods and electronics capabilities offer another effective collaborative model. These manufacturing ecosystems connect designers with production facilities that can handle multiple material types and assembly processes within coordinated workflows. The Wearable Technology Manufacturing Consortium reports that contract manufacturers offering integrated electronics and textile production have grown 72% in the past three years. This approach streamlines production logistics but requires careful coordination to maintain quality standards across different manufacturing processes. Successful implementations typically involve a project management team with expertise in both fashion production and electronics manufacturing to bridge potential communication gaps.

What Framework Supports Successful Collaborative Development?

Successful collaborative development requires structured frameworks that align different expertise areas. Begin with clearly defined roles and responsibilities specifying which partner handles each development aspect. Establish regular integration milestones where aesthetic and technical elements are evaluated together. Create shared documentation systems that accommodate both design specifications and technical requirements. Develop prototype progression plans that gradually increase integration complexity from proof-of-concept to production-ready models. Implement quality control checkpoints that address both fashion accessory standards and electronic safety requirements. These structured approaches prevent misunderstandings and ensure all development aspects progress in coordination.

How Should Intellectual Property Be Managed in Collaborative Sourcing?

Intellectual property management in collaborative sourcing requires careful upfront planning. Clearly define background IP (existing knowledge each partner brings) versus foreground IP (new developments created through collaboration). Establish joint ownership agreements for collaboratively developed elements with specified usage rights. Implement confidentiality agreements protecting both technical specifications and design concepts. Document contribution percentages for patentable developments. Create exit protocols specifying IP rights if the collaboration ends. These protections encourage open collaboration while safeguarding each partner's interests and investments in the development process.

Which LED Technology Companies Offer Custom Development for Wearable Lighting?

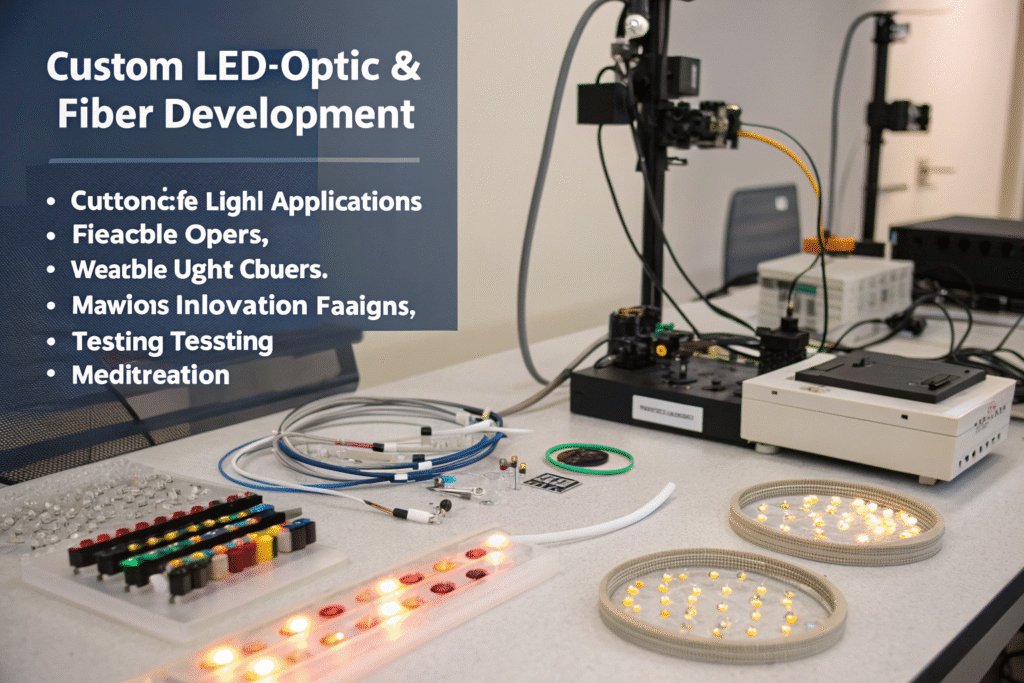

LED technology companies with custom development services can create tailored illumination solutions specifically for hair vine applications. These partnerships offer maximum technical customization but require clearer specification of both technical and aesthetic requirements.

Specialists in miniature and flexible LED systems like NanoLight Technologies have developed ultra-compact light sources specifically for wearables. Their solutions typically feature chip-scale LEDs, flexible printed circuits, and efficient power management systems optimized for battery-operated accessories. According to technical analysis from LEDs Magazine, advancements in miniature LED technology have enabled wearables that were impractical just three years ago due to size and power constraints. These companies typically work from technical specifications to create custom illumination modules that accessory manufacturers can then integrate into their designs, providing lighting expertise without requiring fashion design capabilities.

Optical fiber specialists focusing on side-emitting and end-glow fibers offer another technical partnership opportunity. Companies like Fiberoptic Innovations develop custom fiber configurations with specific light diffusion characteristics, flexibility parameters, and durability features for fashion applications. The Society for Information Display reports increasing collaboration between display technology companies and fashion brands as lighting becomes more integrated into apparel and accessories. These specialists can create fiber solutions optimized for specific hair vine designs, considering factors like bend radius, light uniformity, and color consistency that mass-market fibers may not address.

What Technical Requirements Should Be Specified for Custom LED Development?

Specifying technical requirements for custom LED development requires detailed parameters to ensure satisfactory outcomes. Illuminate specifications should include desired brightness (in lumens or lux at specific distances), color characteristics (CRI, color temperature, or specific RGB values), and uniformity requirements across the illuminated area. Power specifications must define available battery capacity, desired runtime, and acceptable power management approaches. Physical constraints should specify maximum component dimensions, weight limits, and flexibility requirements. Control expectations need to address user interface preferences, lighting pattern options, and connectivity features. Environmental requirements should specify operating temperature ranges, moisture resistance needs, and durability expectations. Comprehensive specifications prevent misunderstandings and ensure development aligns with product vision.

How Can Businesses Evaluate LED Technology Partners for Fashion Applications?

Evaluating LED technology partners for fashion applications requires assessing both technical capabilities and understanding of wearable constraints. Review portfolio examples for evidence of previous fashion or wearable integrations, not just technical component supply. Assess understanding of comfort, weight distribution, and ergonomic considerations specific to hair accessories. Evaluate miniaturization capabilities through examination of previous projects with size constraints. Check experience with low-power designs suitable for battery operation. Verify testing protocols for wearable safety including heat management and electrical isolation. Assess communication abilities to ensure they can translate technical concepts for non-technical team members. Partners who excel in fashion applications demonstrate this combination of technical excellence and user-centered thinking.

Conclusion

Sourcing hair vines with fiber optic lighting requires navigating specialized intersections of fashion design and illumination technology. The most effective approaches combine aesthetic sensibilities with technical expertise through wearable technology specialists, collaborative partnerships between accessory makers and lighting experts, or custom development with LED technology companies focused on wearables. Each sourcing path offers different balances of technical sophistication, customization potential, production scalability, and minimum order requirements.

For businesses developing illuminated hair accessories, success depends on clearly defining both aesthetic vision and technical parameters, then selecting partners whose capabilities align with specific product goals. The most successful implementations balance innovation with practicality, creating products that are both technologically impressive and genuinely wearable. If you're looking to source or develop hair vines with fiber optic lighting, our team at shanghaifumaoclothing has experience connecting fashion brands with appropriate technology partners. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can help navigate the intersection of fashion and technology for your hair accessory development.