I know many buyers are frustrated when suppliers cannot keep up with fashion trends or deliver quality headwear on time. They face late shipments, inconsistent quality, and weak product development. These are real challenges that hurt trust and sales.

Smart technologies such as CAD design, 3D printing, IoT quality control, AI vision inspection, and data analytics are transforming how hair bands are made, ensuring speed, quality, and market accuracy.

This article will explore four key areas where smart technology drives change in hair accessory manufacturing. If you are a buyer, retailer, or brand, these insights will show you why working with an advanced supplier matters.

What Are the Latest CAD & 3D Printing Tools for Fast Samples?

Traditional sampling often takes weeks, and that delay can cost sales. Buyers want fast prototypes to test markets or present to stakeholders. Without quick sampling, opportunities slip away.

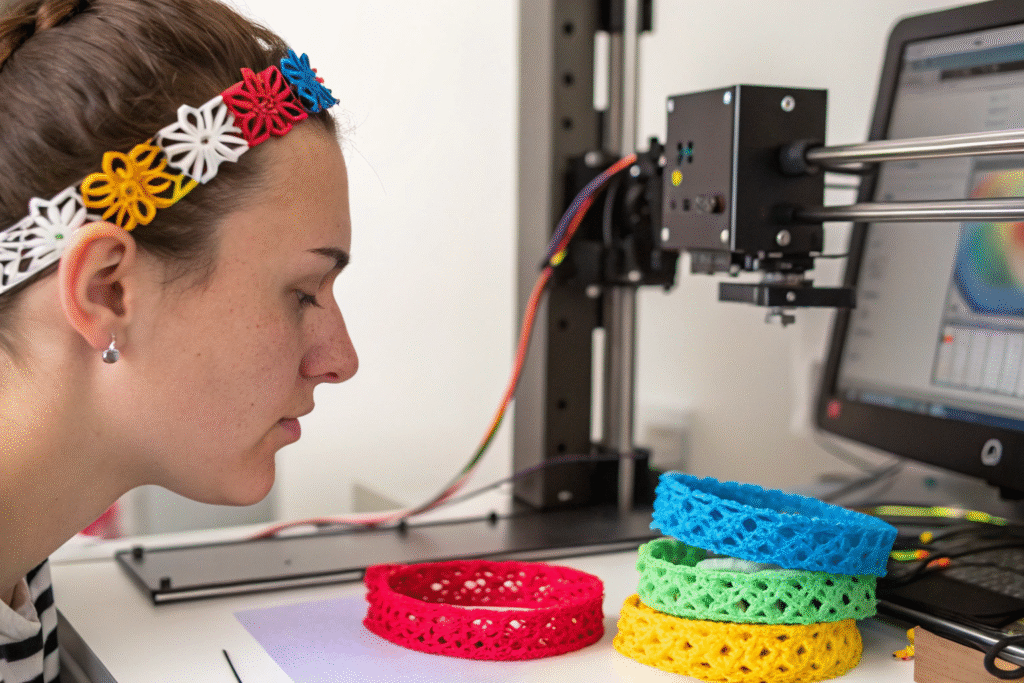

Today, CAD software and 3D printing make hair band prototypes faster, cheaper, and more flexible. With these tools, designs can move from concept to sample in hours instead of weeks.

3D printing allows new shapes like geometric clips or pearl pins to be tested quickly. CAD enables endless customization of fabrics, patterns, and sizes, cutting the risk of design mistakes before bulk production.

What CAD tools help me design faster?

Software like Rhino and SolidWorks help us create precise designs with hair-band-focused libraries. They allow easy edits, ensuring faster turnaround. With digital samples, clients can approve styles before printing.

What 3D printers are best for prototypes?

Resin printers such as Formlabs SLA and selective laser sintering (SLS) machines deliver detailed results for hairpins, bows, and scrunchies. They create highly accurate textures, perfect for intricate pearl designs or lace trims.

Can IoT & Automation Improve QC in Accessories Production?

Quality control is often inconsistent in traditional factories. Manual checks miss details, and errors are found late. This raises costs and delays shipments.

IoT sensors and automation now monitor every step of production in real time, improving reliability and reducing waste.

Factories connect dye vats, weaving machines, and packing stations to IoT dashboards. Automated conveyors and scanners cut mistakes in labeling and packaging, ensuring clients get correct, defect-free shipments.

What IoT sensors help factory stay consistent?

We use humidity and temperature sensors in dyeing rooms to avoid fabric damage. Systems like Siemens IoT2040 monitor embroidery and printing accuracy, alerting staff instantly if data goes outside safe ranges.

How does automation reduce errors in packing?

Automated conveyors use RFID technology to scan each product. If a box lacks an item or contains wrong stock, the system alerts workers. This has cut packing errors by over 50%.

Are AI Visual Inspection Systems Replacing Manual QC?

Manual inspections are slow, subjective, and expensive. Human fatigue leads to missed defects. Clients risk receiving products below their expected standards.

AI vision systems now provide faster, more accurate inspection of hair bands, clips, and scarves, reducing human error.

AI-powered cameras capture every detail—loose threads, chipped acrylic, or missing pearls—ensuring consistent quality even at high production speeds.

How accurate is AI inspection for hair accessories?

Systems like Cognex VisionPro achieve defect detection rates up to 99%. They scan every batch of scrunchies, pearl clips, or lace headbands, guaranteeing consistency and client satisfaction.

Does AI adapt to new designs?

Yes. AI learns from training data. New samples of headbands, turbans, or veils are uploaded, and the system quickly adapts to detect new defect types. This ensures QC keeps pace with fashion updates. Learn more from IBM AI Vision.

What Role Does Data Analytics Play in Market-Driven Production?

Overproduction and mismatched trends waste resources. Buyers want the right items at the right time, not warehouses full of unsold stock.

Data analytics helps factories align production with demand, ensuring market relevance and reducing waste.

Factories now use big data to track order history, social media trends, and retail reports, creating accurate forecasts for hair accessory demand.

How do I track trends accurately?

We pull insights from Google Trends and Alibaba Insights to predict which products—like pearl pins or scrunchies—will sell best in coming months.

Can analytics help with pricing?

Yes. Cost modeling tools like Tableau show how material and tariff shifts affect prices. This lets us offer competitive quotes while protecting client margins.

Conclusion

Smart manufacturing is shaping the future of hair accessories.

- CAD & 3D printing speed up design and sampling.

- IoT & automation guarantee reliable quality.

- AI vision ensures defect-free products.

- Data analytics aligns production with market trends.

At HairAcc, I lead our factory operations across dyeing, embroidery, packaging, and QC. We deliver fast, accurate, and stylish solutions for global buyers.

If you are ready to create your own line of hair accessories—headbands, claw clips, silk scarves, or veils—contact us today. Reach out to our Business Director Elaine at elaine@fumaoclothing.com. Together, we can bring smart, innovative hair accessory collections to your brand.