For a luxury product like printed silk hair scarves, color vibrancy is everything. A fading print doesn't just look worn; it signals poor quality, damaging your brand's reputation for excellence. As a wholesaler or brand, you cannot rely on supplier promises alone. Implementing a systematic, verifiable testing protocol for fade resistance is non-negotiable to protect your investment and ensure customer satisfaction.

The most reliable method for testing fade resistance is a combination of standardized laboratory tests (specifically the AATCC 16 or ISO 105-B02 standards for lightfastness) and practical, in-house simulations for sweat and washing. Lab tests provide scientific, comparable data, while in-house simulations check for real-world vulnerabilities specific to how the accessory is used. Relying solely on one method leaves blind spots.

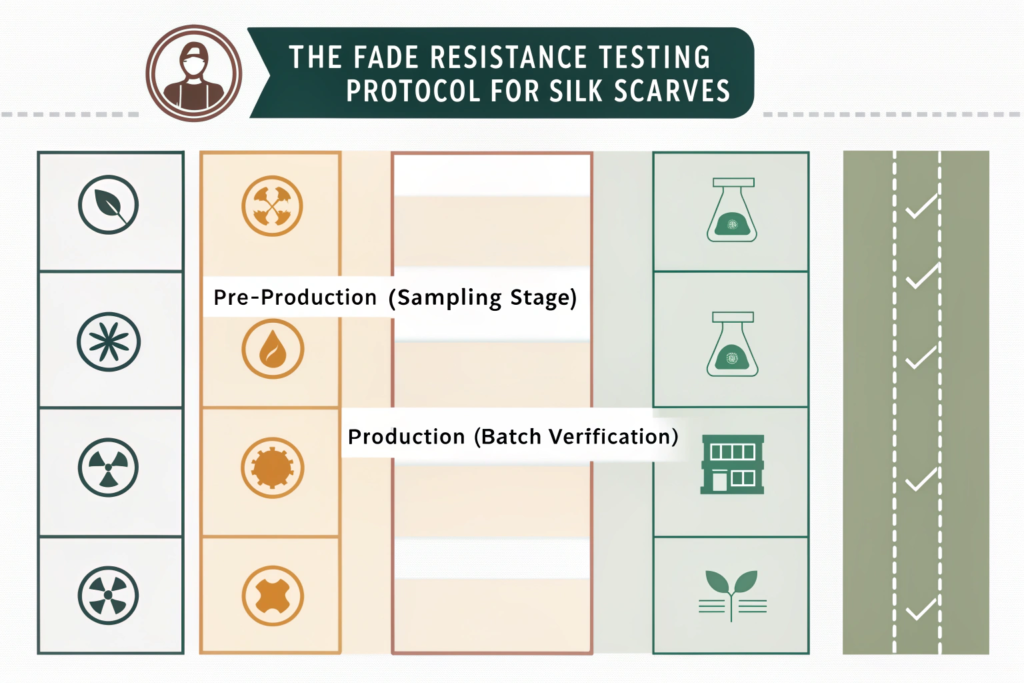

Think of testing as a two-layer defense. The first layer is preventive, conducted during sampling and material approval to catch fundamental dye or print process flaws. The second layer is verification, performed on random units from production batches to ensure consistency. This process directly addresses the core concerns of quality-focused buyers like your client Ron, who prioritize durability and long-term value. Let's explore the specific tests that should be part of your quality assurance protocol.

What are the standardized laboratory tests for colorfastness?

For objective, benchmarkable results, international textile testing standards are essential. They provide a controlled environment to measure how dyes react to specific stressors, allowing you to compare different suppliers or print methods fairly.

The gold standard for fade resistance is the Lightfastness Test, most commonly performed according to AATCC Test Method 16 (Colorfastness to Light) or the equivalent ISO 105-B02. This test exposes the fabric to a controlled, intense light source (usually a xenon arc lamp that simulates sunlight) for a set number of hours. The exposed area is then compared to the original, unexposed fabric using a Grey Scale for Color Change (ranging from Grade 5 - no change to Grade 1 - severe change). For hair accessories expected to have some sun exposure, a minimum rating of Grade 4 is typically acceptable for commercial quality. Another critical lab test is the Crockmeter Test (AATCC 8 / ISO 105-X12) for color transfer, which rubs the printed surface with a white cloth under controlled pressure to check if dry or wet color rubs off—a key indicator of poor dye fixation that often precedes fading.

Why is the Xenon Arc test superior to simple sun exposure?

While hanging a sample in a window seems practical, it is scientifically flawed and inefficient. Natural sunlight's intensity, temperature, and spectrum vary wildly by season, weather, and location, making results inconsistent and non-comparable. A Xenon Arc Fade-Ometer replicates the full spectrum of sunlight, including damaging UV rays, in a controlled, accelerated manner. What might take months or years of intermittent sun exposure can be reliably simulated in dozens or hundreds of hours. This gives you predictive, quantitative data on how the print will hold up over time, allowing for informed material approvals long before bulk production.

What other lab tests should be considered for silk scarves?

Light and rub are primary, but scarves encounter other agents. Consider these tests for a complete picture:

- Perspiration Colorfastness (AATCC 15 / ISO 105-E04): The scarf will contact skin and sweat. This test uses artificial acidic and alkaline perspiration solutions to check for color change or staining.

- Water Colorfastness (AATCC 107 / ISO 105-E01): Tests for color bleeding or change when the fabric becomes damp from humidity or light rain.

- Washing Colorfastness (AATCC 61 / ISO 105-C06): Simulates domestic or commercial laundering. Even if labeled "dry clean only," testing for accidental wash is prudent.

For a manufacturer like Shanghai Fumao Clothing, partnering with or requiring suppliers to provide certified reports from accredited third-party labs (like SGS, Intertek, or Bureau Veritas) for these key tests builds tremendous trust with discerning buyers.

How can you conduct effective in-house quality checks?

Not every batch needs to go to a lab. Effective, routine in-house checks act as a vital screening tool to catch obvious failures and verify consistency from order to order. These simulations are less about generating a grade and more about observing unacceptable failure.

Your in-house toolkit should be simple but systematic. The cornerstone is a modified rub test. Use a manual crockmeter or even a consistent hand-rubbing technique with a white cotton muslin cloth. Rub the printed area firmly 10 times. Inspect the cloth for any color transfer. Any significant transfer indicates poor dye fixation, a direct red flag. Next, perform a spot test for water and sweat. Use an eyedropper to apply droplets of distilled water and a homemade saline solution (to mimic sweat) to an inconspicuous area of the print. Blot with white paper after 30 minutes. Check for both color bleeding into the solution on the scarf and staining of the blotting paper.

What is a simple "sun simulation" test you can perform?

While not a replacement for xenon arc testing, you can create a basic accelerated light exposure test. You will need a powerful, full-spectrum LED or UV lamp (like those used for indoor plant growth or some types of crafting). Mount the lamp at a fixed distance (e.g., 30 cm) from the silk sample in a well-ventilated area. Expose the sample for a set period (e.g., 48-72 continuous hours). Crucially, you must cover half of the sample with thick, opaque cardboard to create a protected control area. After exposure, compare the exposed and covered sections under consistent, neutral lighting. Any noticeable difference indicates low lightfastness. This test is excellent for catching egregious failures quickly.

How should you document and track in-house test results?

Consistency is key. Create a simple Quality Control Checklist for every sampling stage and production lot. The checklist should include:

- Sample ID & Batch Number

- Test Performed: (e.g., Dry Rub, Wet Rub, Water Spot, Sweat Spot, Light Simulation)

- Observation: (e.g., "No staining on crock cloth," "Slight color bleed with saline solution")

- Result: Pass / Fail / Marginal (Requires Review)

- Tester Initials & Date

Taking photographs of the test setup and results (like the white crock cloth after rubbing) is invaluable for creating a visual record to share with suppliers if issues arise, moving discussions from subjective opinion to objective evidence.

What are the common causes of fading and how can they be prevented?

Testing identifies the problem, but prevention requires understanding the root cause. Fading in printed silk is rarely an act of nature; it's usually a consequence of choices in materials and processes.

The primary culprits are low-quality dyes or pigments and improper fixation. Reactive dyes, acid dyes, or high-quality pigments specifically formulated for silk, when properly fixed (often with steam or heat), bond strongly to the fiber. Cheap, generic dyes simply sit on the surface. The printing method itself is a major factor. Digital printing (like inkjet) requires inks with excellent lightfastness ratings. Screen printing must ensure complete dye penetration and fixation. Furthermore, the base silk fabric matters. A poorly degummed or prepared silk will not accept dye uniformly, leading to weak bonds. Finally, the lack of a protective finishing treatment, such as a UV-inhibitor or cationic fixative, can leave the color vulnerable.

How does the choice between dyes and pigments affect fade resistance?

This is a fundamental technical decision. Dyes (like acid dyes for silk) are soluble and chemically bond to the fiber molecules, often resulting in vibrant colors and a soft hand-feel. When well-fixed, they can be very colorfast. Pigments, in contrast, are insoluble particles that sit on the fiber surface and are bonded with a resin binder. They can offer superior lightfastness and wash fastness, but may stiffen the fabric's hand if over-applied. The best print houses will select the colorant system based on the design, desired hand-feel, and required performance. Insisting on knowing which system your supplier uses—and requesting test data for it—is a mark of a sophisticated buyer.

What specifications should you provide to your manufacturer?

Clarity prevents problems. Your purchase order or tech pack should include explicit colorfastness specifications. For example:

- "Lightfastness (AATCC 16): Minimum Grade 4 after 40 hours of xenon arc exposure."

- "Crocking (Dry & Wet): Minimum Grade 4 on the Grey Scale for Staining."

- "Perspiration (Acid & Alkaline): Minimum Grade 4 for color change and staining."

- "All prints must be finished with a UV-protective treatment."

Requiring a pre-production sample signed off by you after your own in-house tests, and stipulating that bulk goods must match this approved sample in performance, gives you contractual leverage. This proactive specification is far more effective than complaining after receiving faded goods.

What is Colorfastness to Washing?

You've assured your customers that your silk scarves are high-quality, but what happens when they need to be cleaned? The fear of colors bleeding in the wash and ruining the scarf (or other clothes) is a major concern for consumers. If your products can't withstand a simple hand wash without losing their vibrancy, you'll be dealing with returns and complaints, undermining the trust you've built with your clientele.

Colorfastness to washing measures a fabric's ability to retain its color and resist bleeding onto other fabrics during laundering. The standard test, AATCC 61, involves washing the fabric sample with a multifiber strip in a specialized machine that simulates home laundering. The results are graded for both color loss and color staining.

At Shanghai Fumao Clothing, we treat wash fastness with the utmost seriousness. A few years ago, we developed a beautiful collection of scarves with deep, saturated jewel tones. Before launching, we ran them through our internal AATCC 61 testing protocol. The initial samples showed slight bleeding. Instead of proceeding, we worked with our dyeing factory to adjust the post-print steaming and washing process. This extra step ensured the reactive dyes were fully fixed to the silk fibers. The final products passed with a grade of 4-5, meaning the colors stayed put. This commitment to quality prevented a potential product recall and reinforced our reputation as a reliable manufacturer.

How does the AATCC 61 test work?

This test is designed to predict how a fabric will behave over many washes.

- A swatch of the printed silk is stitched together with a multifiber test strip. This strip contains swatches of different common fibers (like cotton, polyester, and nylon).

- This composite sample is placed in a stainless steel canister with steel balls and a standardized detergent solution.

- The canister is agitated in a Launder-Ometer, a machine that tumbles it at a controlled temperature for 45 minutes, simulating multiple home washes.

- After the cycle, the silk swatch is evaluated for color loss using the Gray Scale for Color Change. The multifiber strip is evaluated for color staining (bleeding) using the Gray Scale for Staining.

Like the lightfastness test, results are graded from 1 to 5. A high grade (4 or above) for both color change and staining is the mark of a well-made product. For more on testing standards, organizations like Intertek provide commercial testing services based on these AATCC methods.

What production factors influence wash fastness?

Several factors during the manufacturing process determine how well a printed scarf will resist fading in the wash.

- Dye Type: As mentioned in our discussion on lightfastness, reactive dyes are superior for silk as they form a permanent bond with the fiber.

- Post-Print Treatment: After printing, the fabric must be properly steamed. This process sets the dye and initiates the chemical reaction that bonds it to the silk.

- Washing and Rinsing: Following steaming, the fabric must be thoroughly washed and rinsed in the factory to remove any excess, unfixed dye from the surface. Skipping or rushing this step is a common cause of color bleeding in the final product.

When you partner with a manufacturer, ask about their post-printing process. A good supplier will be transparent about these crucial steps.

Conclusion

Testing the fade resistance of printed silk hair scarves is a critical investment in product integrity and brand equity. A robust approach combines authoritative laboratory testing for objective benchmarking with practical, repeatable in-house checks for ongoing batch control. Understanding that fading stems from material and process choices empowers you to specify quality from the start, working with manufacturers to prevent issues rather than just inspecting for them.

By implementing this dual-layer protocol, you transform quality assurance from a hopeful gamble into a managed, predictable process. This delivers the durable, vibrant products that build customer loyalty and protect your margins from returns and complaints. For brands that refuse to compromise on quality, this discipline is a competitive advantage.

If you are looking to develop or source printed silk hair scarves with guaranteed colorfastness and need a manufacturing partner who understands and executes this level of quality control, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's ensure your scarves remain as vibrant as the day they are made.