If you're a wholesaler, retailer, or brand sourcing hair accessories, finding durable products is critical to your reputation and bottom line. Broken clips lead to customer complaints, returns, and damaged brand trust. Finding truly durable clips requires looking beyond surface claims and understanding the key indicators of quality.

To find durable hair clips, focus on three core pillars: the material and manufacturing quality, the design and structural integrity, and real-world performance under stress. By systematically evaluating these areas, you can reliably source products that will withstand daily use and meet your customers' expectations for longevity.

As a manufacturer at Shanghai Fumao Clothing, we build durability into our products from the initial design phase. Here is a practical guide to help you identify and source hair clips that are built to last.

What Materials and Construction Ensure Long-Term Durability?

The foundation of a durable hair clip lies in the materials chosen and how they are processed. High-quality raw materials are essential for resisting breakage, deformation, and wear over time.

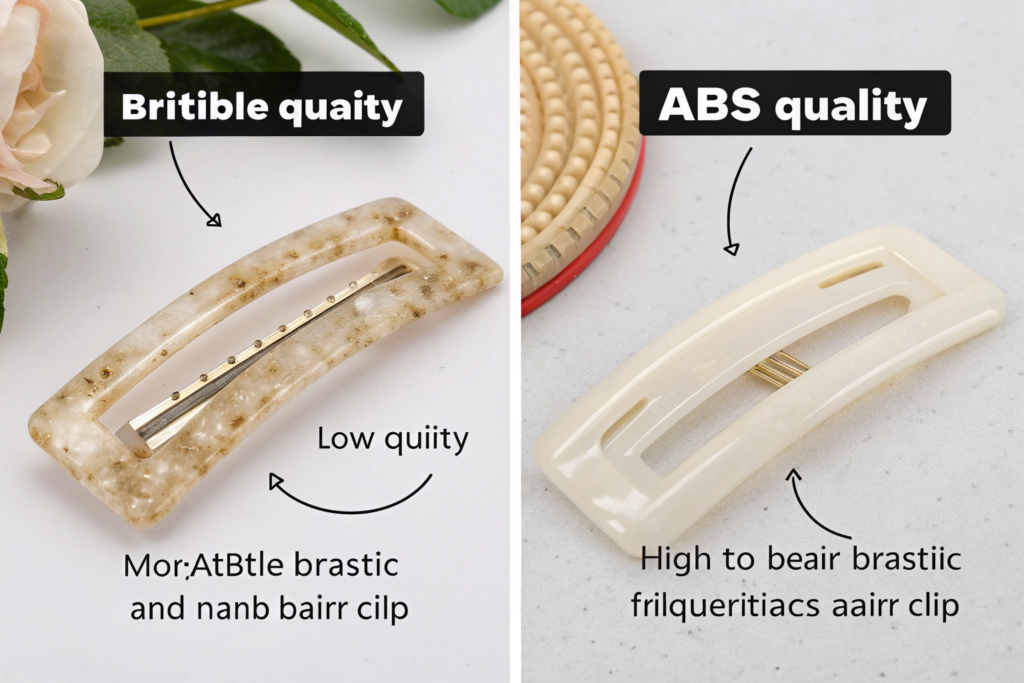

For plastic clips, the specific grade of plastic is crucial. Look for clips made from high-quality, impact-resistant ABS plastic. ABS (Acrylonitrile Butadiene Styrene) is an engineering-grade thermoplastic known for its toughness, strength, and rigidity. It resists cracking and chipping far better than cheaper, brittle plastics. Some advanced products may use specially formulated "high-performance" polymers for even greater flexibility and strength. For metal clips, durability comes from the alloy composition and finishing. A good quality metal alloy, often zinc-based, should feel substantial, not flimsy. A smooth electroplated or powder-coated finish helps prevent rust and corrosion, which weakens the metal over time.

Why Are High-Tension Springs and Solid Hinges Non-Negotiable?

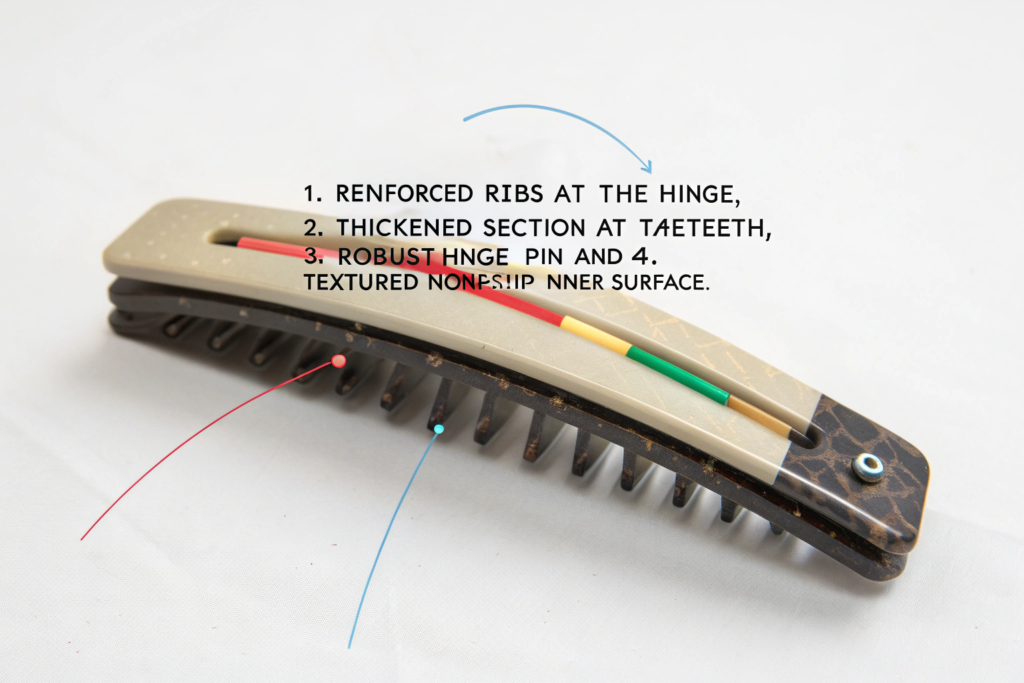

The spring and hinge are the mechanical heart of a clip and the most common points of failure. A durable clip features a high-tension, rust-proof spring that provides a strong, secure hold without losing its elasticity after repeated use. The hinge pin—the rivet or pin that allows the clip to open and close—must be made of sturdy metal and be securely fastened. A loose or poorly attached hinge will cause the clip to wobble and eventually break. For plastic sectioning clips, the design of the clasp mechanism itself must have a "high-tension" feel to ensure a strong grip.

How Does the Plastic Molding Process Affect Strength?

The manufacturing process is as important as the material. Clips made with precision injection molding will have smooth, clean edges without burrs or "flash" (excess plastic). This indicates better mold quality and consistent material density throughout the part, which contributes to overall strength. Clips with rough seams or uneven surfaces often come from worn-out or low-quality molds and are more prone to having weak spots that can initiate cracks under stress.

How Does Smart Design Prevent Breakage in Daily Use?

A durable clip isn't just about strong materials; it's also intelligently designed to distribute stress and avoid weak points. Good engineering anticipates how the product will be used and misused.

A key design feature is reinforcement at stress points. Examine the base of the clip's teeth and the area where the arms meet the hinge. These areas should be thicker or have added material (called a "gusset" or "rib") to prevent snapping. Many clips fail because they are too thin at these critical junctures. For larger claw clips, a design that uses flexibility strategically can prevent snapping. Some modern clips are engineered to be "flexible and unsnappable," bending under pressure rather than cracking. This controlled flexibility, especially in the clip's body, is a hallmark of advanced durability. Furthermore, an anti-slip finish or texture on the gripping surfaces helps the clip hold hair securely without the user needing to overtighten it, which puts excessive strain on the mechanism.

What Are Common Design Flaws That Lead to Early Failure?

When evaluating samples, look for these red flags:

- Visible Mold Lines or "Flash": Rough seams along the edges of plastic clips indicate poor mold quality and can be weak points.

- Thin, Hollow Arms: Clips with arms that feel light and hollow are prone to cracking.

- Teeth That Are Too Long or Thin: Teeth that are disproportionate to the clip's body can easily snap off.

- Weak or Tinny "Click": The sound and feel of the clip closing should be firm and positive. A weak closure indicates a poor spring.

How Does Ergonomic Design Influence Durability?

Ergonomics plays a subtle but important role. A clip that is easy and comfortable to open and close encourages proper use. If a clip is awkward or requires excessive force, users may twist or pry it open in ways that stress the plastic incorrectly, leading to premature failure. A well-designed clip has a smooth, intuitive action that aligns with natural hand movements, reducing unintended misuse.

How Can You Test Durability Before Placing a Bulk Order?

The final test of durability is performance under pressure. You must move beyond product descriptions and conduct hands-on testing to validate a supplier's claims.

Always request physical samples before committing to a large order. Put the sample through a rigorous testing protocol. Try to force it open wider than its intended range and see if the plastic creaks or the hinge shows stress. Open and close it repeatedly (50-100 times) to test the spring's resilience and the hinge's wear. If possible, conduct a "drop test" on a hard surface from a reasonable height. A durable clip should survive a few accidental drops without shattering. For clips that will be used on thick hair, test them with a large section of hair to ensure the hold is secure without excessive strain. According to customer feedback on other products, durability can be a mixed experience, with some items lasting well and others breaking after limited use. This variability underscores the importance of your own pre-screening.

What Questions Should You Ask Your Manufacturer?

A transparent manufacturer will be able to answer detailed questions about their process and quality control. Key questions include:

- "What is the specific grade/type of ABS plastic or metal alloy you use?"

- "Can you explain your quality control process for springs and hinge mechanisms?"

- "What are the most common failure points you've seen in your product testing, and how has your design addressed them?"

- "Do you offer any warranty or guarantee against breakage for bulk orders?"

Asking these questions separates manufacturers who prioritize durability from those who do not.

How to Evaluate a Manufacturer's Quality Control Process?

A manufacturer's commitment to durability is evident in their QC. Ask if they perform batch testing on random samples from production runs. Do they have specific tests for spring fatigue, hinge strength, or plastic impact resistance? A factory with a dedicated QC team and a documented process is far more likely to produce consistently durable goods than one that relies on final visual inspection alone.

Why Do So Many Hair Clips Snap, Slip, or Lose Grip After Just a Few Weeks?

Because durability starts long before the clip reaches your hand—it’s determined by material choice, hinge engineering, and quality control at the factory level. The material choice involves selecting high-grade metals like stainless steel or aluminum alloys that resist corrosion, bending, and wear even after repeated use, ensuring the clip maintains its structural integrity over time.

Where Can You Reliably Source Long-Lasting Hair Clips—Without Overpaying?

Where Can You Reliably Source Long-Lasting Hair Clips—Without Overpaying? When in search of durable hair clips that stand the test of time without breaking the bank, savvy shoppers turn to a variety of trusted sources, each offering unique advantages. Thrift stores and consignment shops are excellent starting points, where vintage or gently used hair clips—often made from high-quality materials like brass, silver, or sturdy plastic—can be found at a fraction of their original cost. These pieces, sometimes decades old, often feature intricate designs, secure spring mechanisms, and reinforced clasps that ensure longevity.

Which Specific Features Should You Physically Inspect Before Buying?

Before making a purchase, whether it's a vehicle, appliance, electronic device, or piece of furniture, physically inspecting key features is crucial to ensure quality, functionality, and value. Here are specific features to examine closely:

-

Structural Integrity: Check for any visible damage, cracks, dents, or rust, especially in metal components, frames, or casings. For vehicles, inspect the body panels for misalignment, paint chips, or signs of past repairs. For furniture, look for wobbly legs, loose joints, or warped surfaces that might indicate poor craftsmanship.

-

Functional Components: Test all moving parts to ensure they operate smoothly. In appliances, open doors, drawers, and compartments to check for proper closure and alignment. For electronics, power on devices to verify screen displays, button responsiveness, and audio output. In machinery, run through basic operations to listen for unusual noises or vibrations

Conclusion

Finding durable hair clips is a deliberate process of forensic evaluation. It requires scrutinizing material specifications, assessing design for stress management, and conducting rigorous real-world testing on samples. By focusing on high-impact materials like quality ABS, robust internal mechanisms, and smart, reinforced designs, you can build a product line known for its reliability.

For wholesalers and brands, sourcing durable accessories directly reduces after-sales issues and builds a reputation for quality that encourages repeat business. It's an investment in customer satisfaction and long-term brand equity.

Partner with a manufacturer that understands material science and robust design. Contact us to discuss how our rigorous material selection, in-house QC, and durable product designs can provide the reliable foundation for your hair accessory line. Reach out to our Business Director, Elaine, at elaine@fumaoclothing.com for a consultation and to request sample clips for your own durability testing. Let Shanghai Fumao Clothing help you build a collection that stands the test of time.