When retailers or fashion brands source printed scrunchie headbands, one of the most common pain points is poor colorfastness. Imagine a customer buying a trendy floral scrunchie only to find the colors fade after one wash or bleed onto clothes in the rain. This not only damages the product’s reputation but also affects the credibility of the brand selling it.

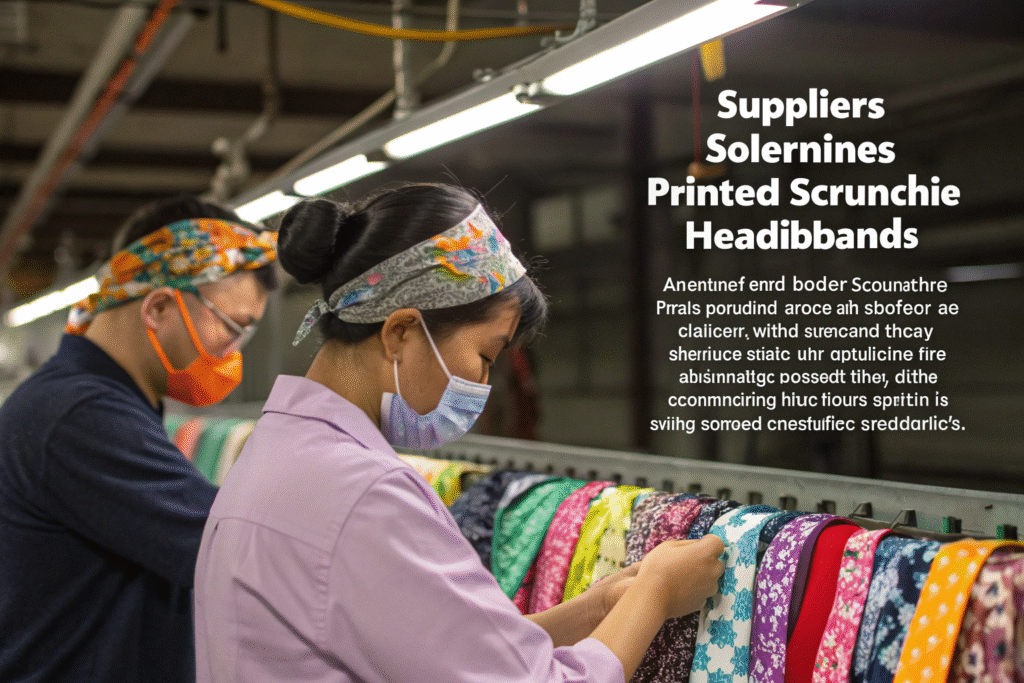

Suppliers ensure colorfastness in printed scrunchie headbands through rigorous fabric selection, advanced printing methods, and strict quality testing to meet international standards.

That means buyers can trust that the product maintains vibrant colors, even after repeated washing, exposure to sweat, or sunlight. For wholesalers, this translates into fewer complaints, reduced returns, and a stronger market reputation.

Fabric Selection and Pre-Treatment Matter Most

Suppliers know that the first step toward reliable colorfastness begins with the raw material. If the fabric cannot hold dyes or pigments properly, even the most advanced printing will fail.

Premium fabrics with strong dye affinity, combined with professional pre-treatment processes like desizing, scouring, and bleaching, ensure optimal absorption of pigments.

Why is fabric pre-treatment so important?

Fabric pre-treatment removes natural oils, wax, or impurities from fibers. For example, untreated cotton can resist dyes, leading to uneven prints. Pre-treatment opens the fibers, making them more receptive to pigment bonding. Many suppliers apply enzyme washing or use eco-friendly chemical scouring to guarantee uniformity.

For more insight on why fabric finishing matters, you can explore Textile World for professional textile updates or check fabric dyeing basics explained on ScienceDirect.

How do suppliers choose fabrics for printed scrunchies?

Most suppliers prefer blends of cotton, polyester, and satin-like synthetics because they offer smooth surfaces for sharp prints. For example, polyester requires disperse dyes that penetrate fibers under high heat. Cotton uses reactive dyes that create strong covalent bonds. The supplier’s fabric choice determines the best printing method, directly influencing colorfastness.

To see how material choice impacts performance, visit CottonWorks for cotton-specific resources or browse Polyester Information for synthetic insights.

Advanced Printing Methods Enhance Durability

Suppliers use modern printing technologies not only to create beautiful designs but also to lock in colors that withstand everyday use.

The choice of printing method—whether digital printing, heat transfer, or sublimation—directly impacts how long the colors remain bright and resistant to fading.

Which printing methods are most effective for scrunchie fabrics?

- Sublimation printing works best on polyester. The dyes transform into gas under heat and penetrate fibers, ensuring deep, permanent coloration.

- Heat transfer printing applies design films onto fabrics, offering vivid results but slightly less breathability.

- Reactive digital printing on cotton ensures sharp detail and excellent wash fastness.

Learn more about the different methods on Textile Today or compare industrial printing systems at Printwear & Promotion.

Do eco-friendly inks affect colorfastness?

Yes, eco-friendly, water-based inks are now widely used. They reduce chemical impact while still achieving excellent fastness. Many suppliers adopt OEKO-TEX® certified inks, which ensure safety and sustainability without compromising performance.

For updates on eco-friendly inks, visit OEKO-TEX® or review sustainable printing practices at Fashion for Good.

Quality Testing Standards for Colorfastness

Even with good fabric and printing, suppliers must validate colorfastness through international testing standards before bulk shipping.

Reliable suppliers follow ISO and AATCC methods to simulate real-life wear, ensuring scrunchie headbands can endure washing, rubbing, perspiration, and sunlight exposure.

What tests are most important for scrunchie headbands?

- ISO 105-C06 (Wash Fastness): Determines how colors behave after repeated laundering.

- ISO 105-E04 (Perspiration Fastness): Simulates sweat exposure, vital for summer headbands.

- ISO 105-B02 (Light Fastness): Tests color resistance under UV exposure.

You can explore the details of these standards on ISO or check test protocols published by AATCC.

How do suppliers grade results?

Color changes are rated using a grey scale from 1 (poor) to 5 (excellent). A high-quality scrunchie headband typically scores between 4–5 across wash, light, and sweat fastness. Buyers should always ask suppliers for a test report before confirming mass production.

More testing guides can be found on SGS or textile compliance details at Intertek.

Packaging and Logistics Also Affect Colorfastness

Even after passing lab tests, poor packaging or storage can compromise colors. Moisture, heat, and friction during transit may cause dyes to rub off or fade.

That is why professional suppliers use moisture-proof packaging, silica gel packets, and careful carton stacking to protect scrunchie headbands on their journey from China to global markets.

How do packaging choices protect headbands?

Suppliers use poly bags or OPP bags for individual scrunchies to reduce friction. For bulk cartons, they line boxes with protective film and insert desiccants to avoid humidity damage. Some even use UV-resistant wrapping to prevent sunlight degradation during long sea voyages.

For more packaging tips, see Packaging Strategies or learn about eco-friendly packaging at GreenBlue.

What role does logistics play in maintaining colorfastness?

Shipping routes and warehouse conditions affect final quality. Delays in humid ports can expose cartons to moisture, while high heat in containers can weaken dyes. Experienced suppliers partner with reliable freight forwarders and conduct pre-shipment inspections to ensure everything arrives intact.

Check out logistics best practices at Freightos or supply chain solutions on Maersk.

Conclusion

Suppliers ensure colorfastness in printed scrunchie headbands by combining careful fabric selection, advanced printing technologies, strict international testing, and protective packaging logistics. For buyers, this means receiving products that remain vibrant and trustworthy in the eyes of their customers.

If you are looking for a reliable partner to produce customized scrunchie headbands or other hair accessories, we invite you to contact our company Shanghai Fumao. Our Business Director Elaine is ready to assist you with product development, sampling, and bulk production. You can reach her directly at elaine@fumaoclothing.com.