Imagine this: your latest shipment of children's hair accessories arrives. A buyer excitedly unpacks a box of sparkly bobby pins, but upon closer inspection, they find sharp, unfinished ends that could easily scratch a child's delicate scalp. In an instant, your reputation for quality is at risk, and worse, you've potentially put a child at risk. This nightmare scenario is why the single most critical detail in producing kids' hair accessories is the rounded-tip safety feature.

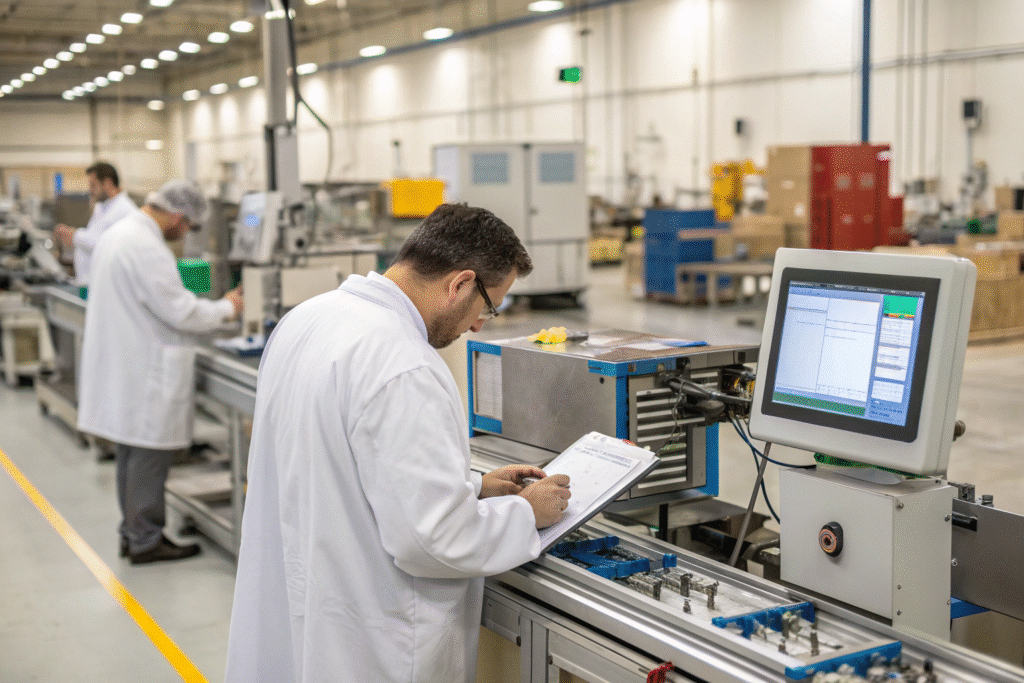

Factories ensure rounded-tip safety on kids' bobby pins through a multi-layered system that integrates stringent international safety standards, specialized manufacturing and finishing processes, and rigorous, repeated mechanical testing. This is not a single step but a comprehensive safety protocol embedded from design to final quality control. The goal is to eliminate all sharp points and edges to prevent cuts, scratches, or puncture hazards. As a leading wholesale fashion hair accessories manufacturer & supplier, Shanghai Fumao Clothing builds this exacting safety-first approach into every production run for our young customers.

For a professional buyer, understanding this process is key to sourcing safe, reliable, and compliant products. Let's dive deeper into the specific standards that define safety, the precise factory techniques that achieve it, and the proof-positive testing that guarantees it.

What Safety Standards Govern Rounded Tips on Children's Accessories?

You can't manage what you don't measure, and safety is no exception. The rounded tip on a child's bobby pin isn't just a "nice-to-have" feature—it's a mandatory requirement defined by a web of international and national safety standards. These regulations provide the exact technical blueprint that factories must follow.

The safety of children's hair accessories is primarily governed by toy safety standards, as these items are considered "childcare articles" meant for use by children. The key frameworks include the European EN 71-1 standard for mechanical and physical properties and the American ASTM F963 Standard Consumer Safety Specification for Toy Safety. These set the foundational rules for eliminating sharp points and edges. Crucially, a new, overarching international standard, ISO 31244-2, was recently published. This "Childcare products — General safety — Part 2: Mechanical hazards" standard, led by Chinese experts, provides a comprehensive 19-dimension framework covering 13 risk scenarios, including hazards from sharp edges. It serves as a vital guide for all subsequent product-specific safety rules.

Compliance doesn't stop at the border. In China, the new mandatory national standard GB 46523-2025 "General safety requirements for children's products" creates a "general + specific" regulatory system. This standard, effective November 2026, acts as a safety baseline for all children's products, mandating strict controls on mechanical and physical performance. For factories like ours at Shanghai Fumao, navigating this complex landscape is a core competency. We actively design our hair clips and bobby pins to meet and exceed the strictest requirements of these markets, ensuring your order is compliant whether it's destined for the EU, US, or anywhere else.

How Do International Standards Like EN 71 and ASTM F963 Define a "Sharp Point"?

These standards transform a subjective idea into a measurable, testable parameter. They define a "sharp point" as a protrusion that can be accessed during use and is sharp enough to puncture skin in a controlled laboratory test. The test typically involves applying a specific force to the tip of the accessory using a calibrated apparatus. If the product penetrates a prescribed depth into a simulated skin material (like certain plastic films), it fails. The standards, therefore, mandate that all accessible points must be mechanically finished to a radius that prevents this penetration. This precise definition is what guides the entire manufacturing and production process for safe hair accessories.

Why Are New Standards Like GB 46523-2025 a Game-Changer for Buyers?

For international buyers, the emergence of robust Chinese national standards like GB 46523-2025 is a significant positive development. It signifies that the domestic regulatory environment is aligning with and often intensifying global best practices, particularly in chemical and mechanical safety. When you source from a factory that is proactively compliant with this new standard, you get an added layer of assurance. It means the supplier's quality control systems are modern, rigorous, and future-proof. This reduces your risk and due diligence burden, as the factory is already operating to a higher, scientifically-backed safety baseline that covers everything from material selection to final testing.

What Specific Manufacturing Processes Create a Safe Rounded Tip?

Knowing the standard is one thing; achieving it consistently across millions of tiny metal pins is another. The journey from a coil of metal wire to a safe, rounded-tip bobby pin involves several critical and controlled manufacturing stages.

The creation of a safe rounded tip is a deliberate three-stage process within the factory: forming, deburring, and polishing. First, the wire is cut and bent into the classic bobby pin shape. This cutting operation inevitably leaves a sharp, sheared end. Next, the crucial deburring stage removes these rough, sharp protrusions (burrs). This is often done via tumbling, where thousands of pins are placed in a vibrating or rotating drum with abrasive media. The media grinds down the sharp edges through constant friction. Finally, a polishing or barrel finishing step smooths the metal to a uniform, lustrous finish, eliminating any microscopic roughness and creating the final safe, rounded contour.

The choice of process depends on volume, material, and the desired final quality. High-volume production of standard bobby pins and hair pins typically relies on efficient barrel tumbling. For more delicate or premium items like decorated hair sticks or certain hair clips, manual or semi-automatic polishing on buffing wheels might be used for greater control. The key is that the process is not left to chance. At Shanghai Fumao, our integrated factory setup allows us to control these parameters directly. We select the appropriate abrasive media, control the tumbling duration, and monitor outcomes to ensure every batch meets the strict safety specifications before moving to the next stage of packaging.

How Does the Tumbling and Polishing Process Eliminate Sharp Edges?

Tumbling is a mass-finishing technique critical for safety. Pins are loaded into a perforated barrel with a mixture of abrasive media—often small, pre-formed ceramic or plastic chips in various shapes. As the barrel rotates, the media and pins move in a complex cascading motion. This creates countless gentle collisions where the abrasive media acts like thousands of tiny files, uniformly wearing down the sharp points and edges. The process is timed; running it too short leaves sharp edges, while too long can damage the pins. Factories use sample checks to find the optimal cycle. This process is essential not just for safety but also for the final feel of the product, ensuring no snags on hair or skin.

What Role Does Material Selection Play in Tip Safety?

The safety of the final tip is intrinsically linked to the raw material. The metal wire used must have the right combination of flexibility for use and malleability for finishing. A wire that is too hard may fracture or create persistent, difficult-to-remove burrs during cutting. A wire that is too soft might not hold its shape. Factories specify wire with precise tensile strength and composition. Furthermore, the material must be compatible with the finishing process; it must be able to be polished to a smooth finish without corroding. This is part of the broader material quality requirements emphasized in new standards like GB 46523-2025. A professional manufacturer will have stringent supplier quality agreements for raw materials, as safety truly begins at the very start of the supply chain.

How Are Rounded Tips Rigorously Tested and Verified?

After manufacturing, the assumption of safety is not enough. Verification through objective, replicable testing is the final and most crucial gate. This is where factory claims are substantiated with hard data for buyers.

Rounded tips are verified through a series of mechanical and physical safety tests designed to simulate real-world use and abuse. The primary method is the sharp point test, conducted using a calibrated apparatus that applies a fixed force to the tip. The accessory passes only if it cannot penetrate a specified test gauge. Equally important is the sharp edge test, which checks for hazardous edges along the pin's length. Furthermore, tension and torque tests are performed to ensure the pin's functional parts don't break during normal use to create new sharp points. Reputable factories conduct these tests both in-house and via independent third-party laboratories to provide objective certification for buyers.

Testing is not a one-time event but a frequency-based check integrated into quality control. A robust QC plan includes testing raw wire, testing samples from the beginning, middle, and end of a production run (IPP, DUPRO, FRI), and testing final pre-shipment samples. This statistical approach catches process deviations. For example, if a tumbling barrel's abrasive media becomes worn out, the tips from that batch may be insufficiently rounded. Routine testing would flag this immediately before the entire batch is completed. As an experienced supplier, we at Shanghai Fumao Clothing maintain a dedicated inspection factory and QC team precisely for this purpose. This systematic verification is your best assurance that every hair clip, headband, and accessory in your shipment is consistently safe.

What Common Tests Simulate Real-World Use and Abuse?

Beyond the basic sharp point test, responsible factories perform "abuse tests" that mimic how children might use (or misuse) a product. These include:

- Drop Test: The accessory is dropped from a height onto a hard surface to see if it breaks or creates sharp fragments.

- Torque Test: Applicable to any rotating parts (like on some decorative clips), this ensures they cannot be tightened or loosened to a dangerous point.

- Tension Test (Pull Test): For assembled items, this test applies a strong pull to glued or clasped components to ensure they don't separate into small, swallowable parts with potential sharp edges.

These tests are often detailed in standards like EN 71-1 and ASTM F963, and they form a critical part of a complete safety assessment.

Why is Third-Party Laboratory Certification Essential for Buyers?

While in-house factory testing is vital for process control, certification from an accredited third-party lab is the gold standard for market access and buyer trust. Labs like those participating in the EPTIS proficiency testing scheme demonstrate high competency in executing standards like EN 71. They provide an unbiased report that serves as your legal and commercial evidence of compliance. For a buyer, especially one like Ron who values quality and manages tariff and security risks, requesting up-to-date test reports for the exact product is a non-negotiable step. It mitigates your risk of customs rejections, liability issues, and costly recalls. A professional factory will readily provide these documents and often guide you on the specific certifications required for your target market.

What Should Buyers Look for in a Supplier's Safety Documentation?

For a buyer, the proof is in the paperwork. A supplier's commitment to safety is transparently reflected in the documentation they can provide and the processes they can describe. This is your due diligence toolkit.

A credible supplier should readily provide a clear documentation package that proves compliance. This includes: 1. Test Reports: Current, product-specific test reports from internationally accredited laboratories (e.g., using ISO 17025 standards) for the relevant markets (EN 71, ASTM F963, etc.). 2. Material Certifications: Statements or test reports for raw materials, confirming they are free from harmful substances like heavy metals or excessive phthalates, which is a key part of new standards like GB 46523-2025. 3. A Detailed Quality Control Plan: This document outlines their in-process checkpoints, sampling sizes, and testing frequency. 4. Product Specifications: Technical sheets that detail the exact dimensions, materials, and safety features of the product.

When evaluating a supplier, ask pointed questions about their process: "How do you specifically deburr and round the tips on your bobby pins?" "Can you walk me through your in-house QC tests for sharp points?" "What happens if a batch fails the final inspection?" Their answers will reveal their depth of knowledge and operational discipline. At Shanghai Fumao Clothing, we encourage these discussions. We understand that for our clients—large wholesalers, brand owners, and e-commerce sellers—this documentation isn't just paperwork; it's the foundation of a trustworthy partnership and safe supply chain. Our professional customer energy is focused on making this complex aspect of sourcing clear and manageable for you.

How Can Buyers Verify the Authenticity and Relevance of Test Reports?

Don't just accept a report; scrutinize it. Check the date to ensure it's recent (typically within the last 1-2 years). Verify that the testing laboratory is accredited (look for logos like CNAS, UKAS, etc.). Most importantly, confirm that the report's "Sample Description" matches the exact product you are ordering—the same material, design, and size. A report for a "metal hair clip" may not be valid for a "plastic and metal alloy hair clip." Ask the supplier to highlight the specific tests for sharp points (e.g., EN 71-1 Clause 8.14) and the pass/fail results. This level of review separates serious manufacturers from mere traders.

What Questions About Production Safeguards Reduce Sourcing Risk?

Beyond documents, ask operational questions that uncover their safety culture:

- "Are your safety testing instruments calibrated regularly?"

- "How do you train your QC staff on safety standards?"

- "Can you show me a failed sample and describe the corrective action process?"

A factory with integrated processes, like our own setup with cooperative dyeing, printing, and dedicated inspection facilities, is inherently better positioned to control every variable affecting safety. This vertical integration is a strong indicator of reliability and a key factor in ensuring fast production of high-yield, safe products.

Conclusion

Ensuring rounded-tip safety on children's bobby pins is a sophisticated, non-negotiable process that blends regulatory compliance, precision manufacturing, and relentless verification. It begins with designing to strict international standards like EN 71, ASTM F963, and the new GB 46523-2025, continues through controlled forming and tumbling processes, and is cemented by rigorous mechanical testing and comprehensive documentation.

For wholesalers, brands, and retailers, partnering with a factory that has this process deeply ingrained is the simplest path to mitigating risk and ensuring customer safety. It transforms safety from a worry into a verified component of your product.

If you are looking to develop or source safe, high-quality, and fashionable hair accessories with confidence, we invite you to discuss your project with us. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start a conversation about your next order. Let Shanghai Fumao Clothing be your trusted partner in creating beautiful and safe accessories for the global market.