As a manufacturer deeply embedded in the global accessories supply chain, I can offer a direct answer: you will not find ready-made "nanofiber sweatbands" on mainstream wholesale platforms like Alibaba. This product is currently at the frontier of material science, primarily existing in research labs and advanced development pipelines.

However, for professional buyers, brands, and serious entrepreneurs looking to pioneer this high-performance category, the path to sourcing or creating them is clear. It involves moving from generic B2B search to strategic partnership development. This guide outlines the actionable routes to bring a next-generation sweatband from concept to the hands of elite athletes.

What Defines a True "Nanofiber" Sweatband?

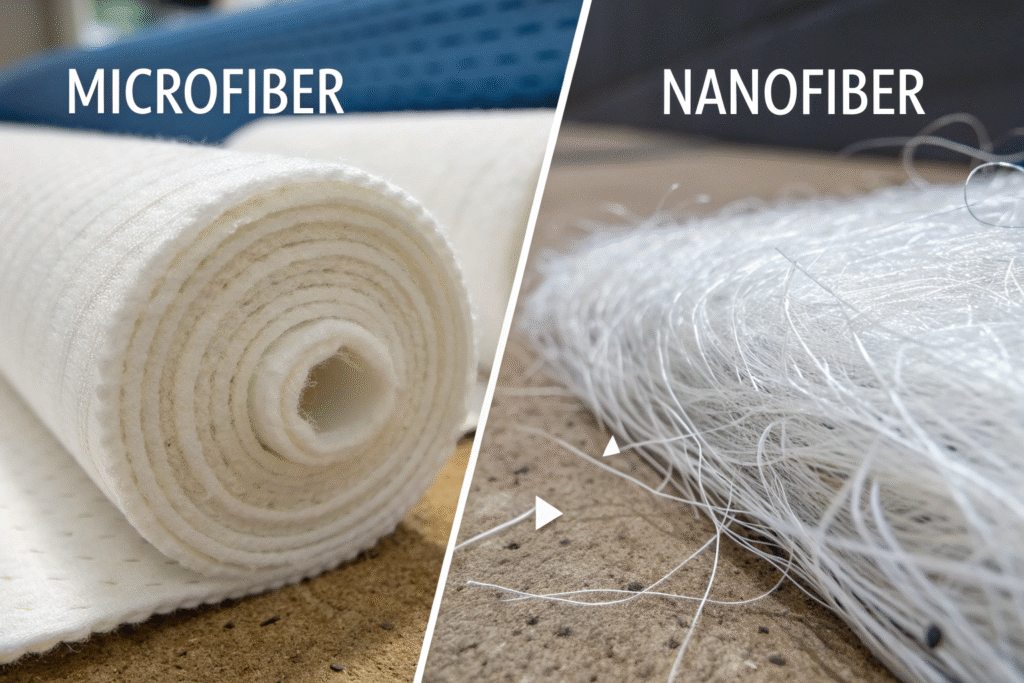

The term "nanofiber" is often misused in marketing. For a professional-grade product, it must refer to a non-woven fabric where the individual fiber diameter is measured in nanometers (one billionth of a meter). This structure creates a massive surface area, enabling exceptional properties like superior moisture-wicking, bacterial filtration, and targeted functionality. It's a material leap, not just an incremental improvement over standard polyester or terry cloth.

What Performance Advantages Do Nanofibers Offer?

The core advantages are transformative. First is unmatched moisture management. The capillary action in a nanofiber web pulls sweat away from the skin and spreads it across a vast surface area for rapid evaporation, keeping athletes drier. Second is breathable protection. The dense network can act as a physical barrier against dust, pollen, and even certain bacteria, without sacrificing air permeability like a plastic film would. Third is the potential for advanced functionality. During the production process (like electrospinning), active ingredients such as antimicrobial copper oxide nanoparticles or cooling minerals can be directly integrated into the fibers themselves, not just coated on top.

Why Aren't They Available Off-The-Shelf?

True nanofiber textiles for wearable applications face significant production and commercial hurdles. The primary method, electrospinning, is often too slow and costly for high-volume consumer goods like sweatbands. There are also questions about the long-term durability and wash resistance of some nanofiber mats under intense friction and repeated laundering. Consequently, most commercial "nano" claims in sportswear refer to nano-finishes or treatments applied to conventional microfibers, which offer some benefits but are not the same as a true nanofiber fabric.

How Can Professional Buyers Source This Technology?

For serious procurement, the strategy shifts from finding a supplier to enabling a supplier. You are not buying a catalog item; you are co-developing a technical specification. Your partners will be specialized material innovators and advanced manufacturers, not general accessory traders.

| Table: Sourcing Pathways for High-Tech Sportswear Components | Pathway | Description | Example Partners/Leads | Best For |

|---|---|---|---|---|

| 1. Functional Fabric Specialists | Companies that develop and sell innovative fabrics. They may have nano-enhanced or analogous high-performance materials suitable for cutting and sewing into bands. | Shanghai Fumao Clothing (as a development hub), Schoeller Textil AG, Polygiene®-treated fabrics | Brands seeking to use a proven, scalable performance fabric in their own designs. | |

| 2. Technical Non-Woven Manufacturers | Factories that produce non-woven fabrics for medical, filtration, or high-tech applications. They may have electrospinning capabilities. | Companies in sectors like air filtration or medical disposables that work with nanofiber mats. | Large-scale buyers willing to fund minimum order quantities (MOQs) for custom material development. | |

| 3. Research & Technology Transfer | Partnering directly with universities or labs that hold patents for wearable nanofiber technologies. | Technology transfer offices of universities publishing relevant sports science or textile engineering research. | Major sportswear corporations aiming for a proprietary, patent-protected market advantage. |

Who Are the Real Decision-Makers in This Supply Chain?

To move a project like this forward, you need to engage with R&D Managers at functional fabric companies or Business Development Directors at advanced material manufacturers. These individuals understand technical specifications and development timelines. A general sales representative for ordinary sweatbands will not have the authority or knowledge to support such an innovation.

What Are the Realistic Development Steps?

Expect a phased process. First, material sourcing and testing: procuring swatches of potential high-tech fabrics (e.g., phase-change material linings or silver-ion treated fabrics) for lab and wear-testing. Second, prototyping and sampling: a factory like ours can create multiple physical samples for athlete feedback. Third, performance validation: conducting tests on absorbency, drying time, and skin comfort. This collaborative, iterative approach mitigates risk and ensures the final product meets professional standards.

What Are the Practical Alternatives Available Now?

While true nanofiber bands are in development, elite athletes today use sweatbands made from the most advanced microfibers and smart material blends on the market. These represent the current pinnacle of practical, mass-producible performance.

Which Advanced Materials Are Setting the Current Standard?

The current gold standard includes fabrics like Coolmax®, which uses engineered polyester channels to wick moisture; Celliant®, which incorporates mineral-infused fibers aimed at improving circulation and recovery; and merino wool blends, which offer natural odor resistance and temperature regulation. Another key innovation is the use of hydrophilic and hydrophobic yarns in specific patterns to directionally move sweat away from the skin. These technologies are proven, durable, and immediately available for production.

How Can You Customize with Today's Best Tech?

As a manufacturer, we help clients build the best possible product with available technology. This means:

- Material Layering: Combining a soft, skin-friendly inner layer (like a silver-ion antibacterial fabric) with a fast-drying outer layer.

- Ergonomic Design: Engineering the band's fit, width, and stitching to stay secure during explosive movement without creating pressure points.

- Integrated Features: Adding silicone grippers on the inside to prevent slipping, or using flat-lock seams to eliminate chafing. This is where our ODM/OEM expertise turns a high-tech fabric into a finished, professional-grade accessory.

Conclusion

For professional buyers, the quest for nanofiber sweatbands is not a simple procurement task but a product development mission. The immediate opportunity lies in leveraging the most advanced functional fabrics and manufacturing expertise available today to create a superior product that meets the rigorous demands of elite athletes.

At Shanghai Fumao Clothing, we bridge the gap between material innovation and commercial production. If you have a vision for a next-generation performance sweatband, we have the supply chain connections, prototyping capability, and technical partnership approach to help you develop, test, and manufacture it. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start a technical discussion about your performance requirements.