I run HairAcc in China. Every week we ship cartons that include headbands, scrunchies, claw clips, bobby pins, pearl pins, hair sticks, scarf headbands, and veils. Buyers like Ron want stable quality and clear paperwork. They also want quick delivery and predictable schedules. Mixed SKUs make quality control more difficult. If one sub-SKU fails, the whole shipment can stop.

The solution is simple. We streamline QC by moving inspections earlier, grouping items into categories, and keeping sampling clear. We also connect labels to digital specifications. Finally, we run layered checks at each factory step and finish with strong packaging validation. This system reduces mistakes and keeps shipping on time.

I will explain how we do this at HairAcc. We manage production across our main headwear factory, partner dyeing houses, printing shops, embroidery units, an inspection plant, and a packaging facility. Each stage has a role. Each team owns part of QC.

AQL Sampling for Mixed Hair SKUs: What Works?

A single sampling plan does not work for mixed shipments. Scrunchies fail differently than claw clips. Embroidered headbands carry stitching risks that pearl pins do not. If we use one AQL for all, we lose control.

I now build a category-based AQL system. I divide products into groups. Fabric-elastic items go together. Rigid plastic and metal items go together. Embellished or decorated items form another group. Each group has its own rules. I use simple sample sizes and clear defect definitions. This avoids arguments later.

Inspectors follow defect cards with photos. A broken spring in a claw clip is critical. A missing bead in a pearl pin is major. A seam gap on a headband is also critical. Each rule sits inside our QC app. Inspectors tap and confirm quickly. This keeps checks fast and consistent.

Should We Use One AQL Table Across All Categories?

I tried one table before. It caused gaps. Scrunchies needed more elastic checks, while clips got over-checked. Now I divide by risk. I use references from ASQ and ISO 9001. I also review third-party standards at SGS. This gives buyers confidence and reduces disputes.

How Do We Define Defects So Teams Judge the Same?

Defects must be clear. I prepare photo cards. I also align with Intertek test methods and OEKO-TEX chemical safety rules. Sharp edges and open seams are always critical. Inspectors see the same pictures, so they judge the same way.

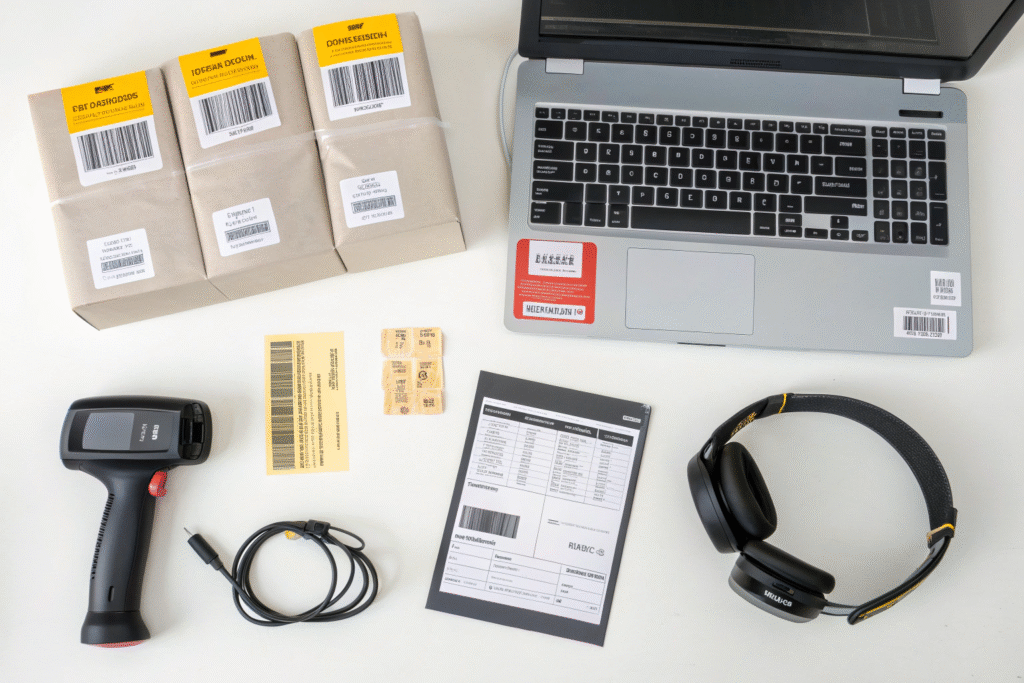

Barcode, Labels, and Specs: How Do We Prevent Mix-Ups?

Labels create discipline. Mixed shipments fail when labels drift from specs. I once had a shipment rejected because two scrunchie sets swapped inner cards. Now I tie every barcode to a digital spec.

Scanners read barcodes and open the golden spec. The spec shows material, color, and packing design. Packers see the correct photo and the right card. This prevents mistakes. I also use GS1 barcodes and carton SSCC codes from GS1.

If labels change, the system updates the ASN. If a carton fails scan, it does not load. This “no scan, no pack” rule keeps cartons aligned.

Which Barcode Standards Reduce Disputes at Receiving?

I use GTIN and SSCC to meet global rules. I align with TARIC for EU and CBP for U.S. customs. I proof carton marks with templates. This stops relabeling at the buyer’s side.

How Do We Tie Labels to Live Specs So Pickers Never Guess?

Pickers see specs live. If a scarf is silk, they also see care symbols and dye rules from REACH. If a clip is acetate, they see safety notes from Eastman. Packers never guess. Errors fall sharply.

Layered Inspections: Where Should We Inspect to Save Time?

One final inspection cannot catch everything. Problems start earlier. We add checks at each step. Dye houses test color. Printing shops test registration. Embroidery checks thread tension. Assembly checks sharp points. Packaging checks carton strength.

Each station runs three or four checks. Each owner signs in the app and uploads a photo. If a failure appears, rework happens on the same floor. This speeds the process and keeps quality stable.

Where Do Third-Party Labs Fit Without Slowing Us Down?

Labs protect compliance. I use SGS and Intertek for high-risk materials. For Europe, I align with REACH. For U.S., I follow CPSC safety rules. For textiles, I use OEKO-TEX STANDARD 100. I test with PP samples so reports are ready before shipment.

How Do We Validate Packaging Strength for Real Routes?

I test cartons for the real journey. If the route uses rail-sea-truck, I simulate drops and humidity cycles. I also follow carrier guidance from Maersk and Flexport. I confirm strength using drop and crush tests. I watch freight dashboards at Freightos. This protects cartons before peak season.

Final Packaging, ASN, and Handover: How Do We Ship Faster?

Final QC is about handover. I match mixed cartons to the ASN. If I adjust late, I update ASN before loading. I audit pallets. I photo-scan each face. I share a pack of invoice, list, CO, and test reports with buyers.

This clean package builds trust. Buyers judge suppliers on delivery accuracy. I want HairAcc to “just land” shipments with no delays.

What Goes into a Clean ASN That 3PLs Love?

I use carton-level SSCC and EDI when needed. I align with FedEx and DHL. For containers, I follow Maersk guides. I also check Incoterms at ICC.

How Do We Reduce Payment and Customs Delays?

I match invoices with HS codes from CBP and TARIC. I use secure programs like Alibaba Trade Assurance. I also attach memos for mixed material shipments. This prevents customs holds and payment delays.

Conclusion

Mixed hair product shipments are complex, but QC does not need to be slow. We segment AQL by risk. We anchor labels to live specs. We inspect at each stage. We finalize with strong ASNs and packaging. This system lowers defects and speeds shipping.

At HairAcc, we use this playbook daily. We manage multiple factories and a full QC team. We deliver across Europe, the U.S., and Russia. We also navigate tariff risks with clear routing. If you want to launch your own headwear collection, contact Shanghai Fumao. Reach our Business Director Elaine at elaine@fumaoclothing.com. We will prepare samples and a QC plan tailored to your SKUs.